Digital Diagnostic Monitoring (DDM) is a common feature in optical modules that provides real-time monitoring and diagnostic information about module performance and status. DDM enables network administrators to better understand the operation of optical modules, enabling troubleshooting and performance optimization.

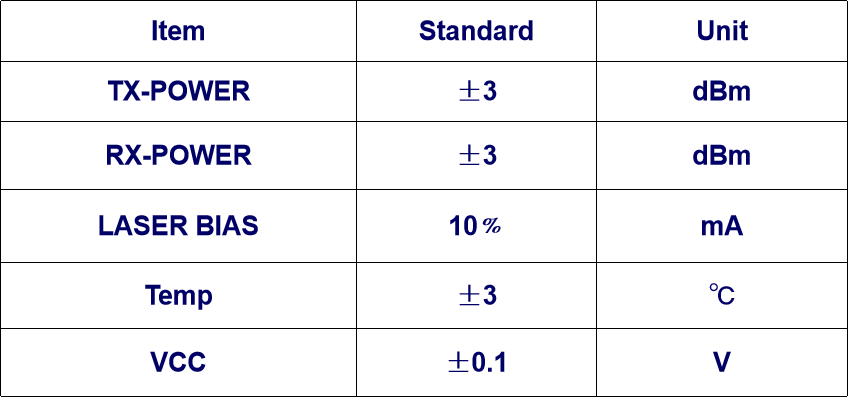

The five real-time measurement parameters monitored by DDM are:

How does DDM work?

DDM functionality is achieved by embedding a set of monitoring parameters and sensors in the optical module. These parameters include transmit power, receive power, operating temperature, voltage and other related indicators. The optical module communicates with external devices such as switches through internal digital chips, and transmits real-time monitoring data back to the control device.

Advantages of DDM

DDM provides network administrators with real-time monitoring and diagnosis functions for optical module performance and status. Through DDM, administrators can obtain monitoring data of key parameters, quickly troubleshoot, optimize network performance, and improve overall manageability and reliability. With the advancement of optical communication technology, more and more optical modules will support DDM, providing greater convenience for the deployment and maintenance of optical networks.